- Our Products

Flexible

Hard Film

Fit-in

Container

- Technology

- Applications

- About

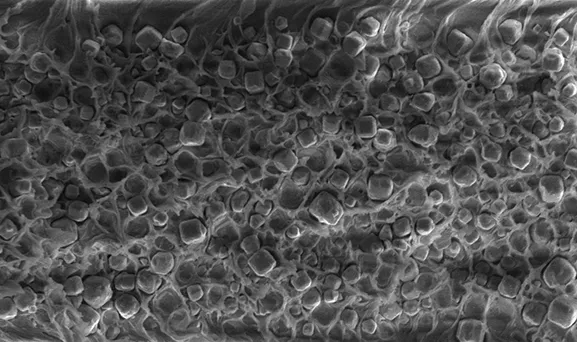

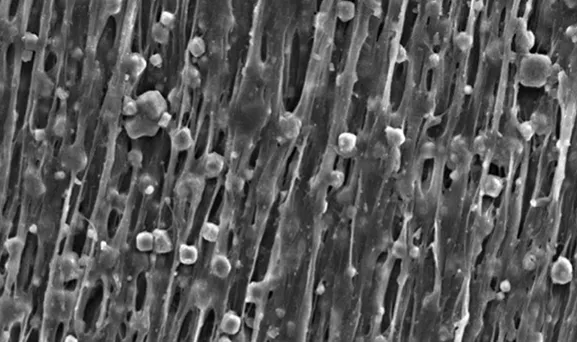

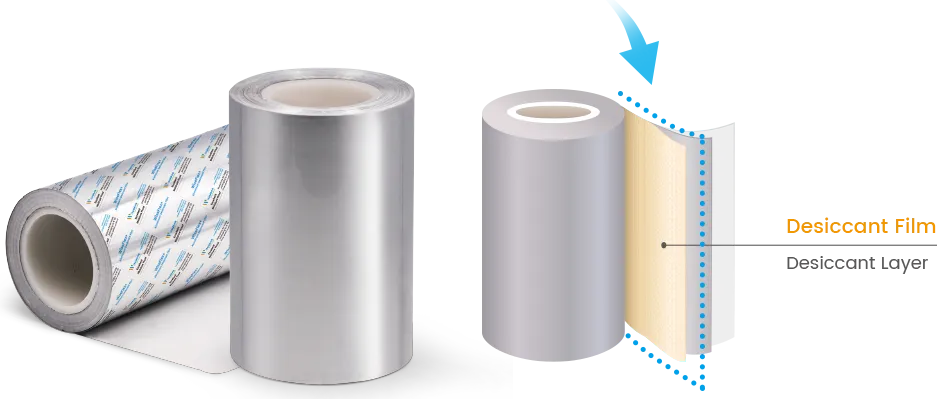

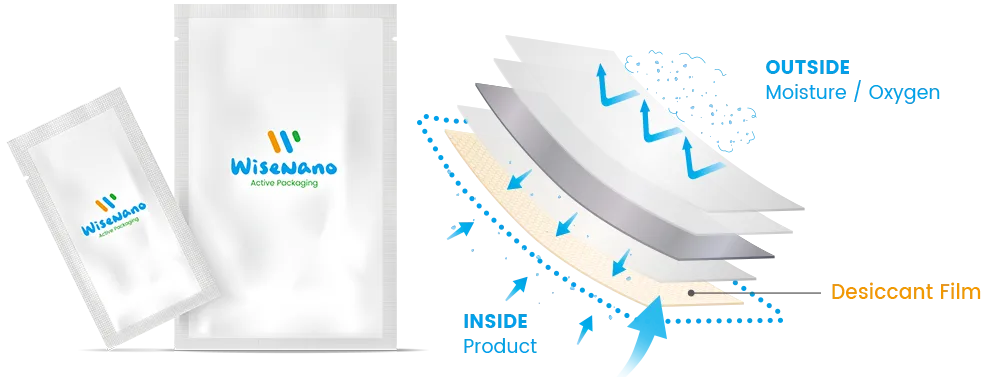

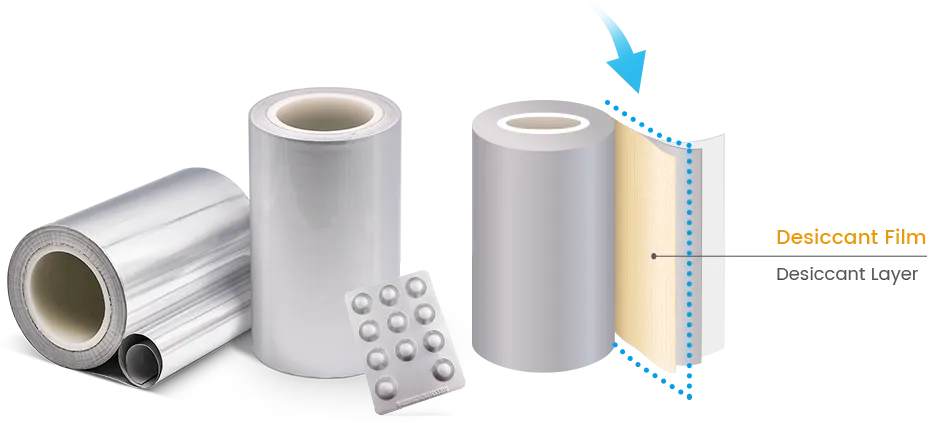

WiseFlex desiccant film possesses the characteristic of an evenly distributed and fine moisture-absorbing pore structure. During the process of moisture migration, water molecules pass through the pores of the desiccant layer and are absorbed by the desiccant particles. The more uniform and fine the pore distribution of the desiccant layer, the easier water molecules can be absorbed by the desiccant particles, leading to quicker and more effective moisture absorption. The even and dense pore distribution of WiseFlex desiccant film enables efficient and rapid moisture absorption.

The moisture absorption capacity of the desiccant layer is influenced by thickness and composition variations. Under identical environmental conditions (25°C, 40% RH):

| Thickness | Moisture Capacity |

|---|---|

| 60 μm | ≥ 4.0 g/㎡ |

| 80 μm | ≥ 6.0 g/㎡ |

| 110 μm | ≥ 9.0 g/㎡ |

The primary component of the desiccant film is PE, making it suitable for various film composites (PET, PA, PP, Alu, Fiber, etc.) and enabling the production of diverse composite films, pouches and bags.

It can be widely employed in the packaging of moisture-sensitive products requiring humidity control. Sectors including pharmaceuticals, health supplements, food, cosmetics, precision electronic instruments, and military industries can all benefit from its use.

WiseFlex Desiccant Film

Please fill in your information and submit this order form, our sales representative will contact you soon