Art of Pharmaceutical Packaging

The Integration of Medicine Blister Packaging and Desiccant Sheets

Secondly, attention must be given to the space between the blister pack and the composite aluminum foil pouch. While blister packs and aluminum foil pouches play a pivotal role in safeguarding medicines, the flow of air between them may introduce humidity, posing potential risks to the medicines. To address this issue, an effective method is needed to maintain a dry environment within the packaging. The current market includes instances where a desiccant pack is placed in the middle, but this can lead to friction and compression with the blister pack, impacting aesthetics.

In order to better support the stability and effectiveness of medicines, WiseNano has introduced WiseSheet polymer desiccant sheets into pharmaceutical blister packaging through meticulous selection and configuration. This innovative polymer desiccant sheet further enhances the functionality and aesthetics of blister pack packaging.

Two solutions are proposed:

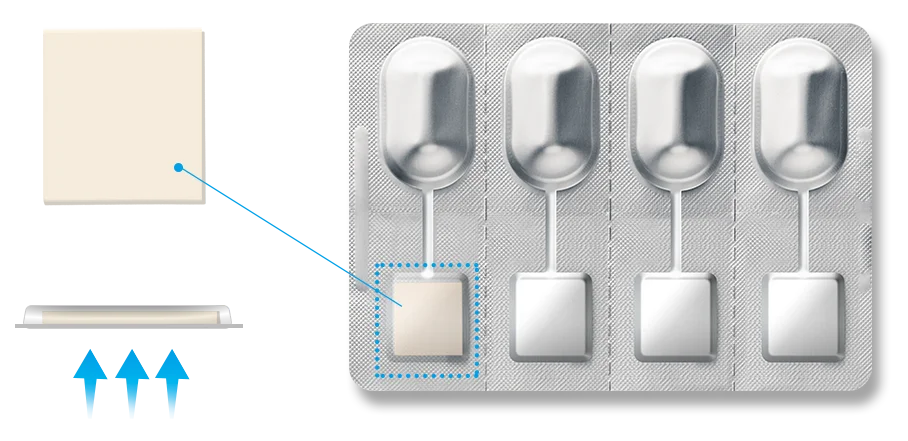

Solution 1:

Reserve a designated space within the blister pack for placing desiccant sheets, ensuring that each blister pack is connected to a desiccant sheet to maintain a continuous dry environment. In this solution, WiseSheet polymer desiccant is an ideal choice. By selecting desiccant sheets of different thicknesses (0.6mm, 1mm, and 2mm), excellent protective functions are provided while maintaining a smooth and appealing appearance.

Solution 2:

To address the airflow issue between the blister pack and the composite aluminum foil pouch, and to avoid the problems associated with placing desiccants that may be compressed and affect aesthetics, WiseSheet polymer desiccant can be adhered to the interior wall of the aluminum foil pouch. This design ensures the continuous maintenance of a dry environment without requiring additional packaging space. This approach not only efficiently utilizes limited space but also maintains the neat and aesthetic packaging, without affecting the appearance and display of medicines.

Furthermore, the multiple thickness options of WiseSheet polymer desiccant sheets allow them to adapt flexibly to various packaging needs. This solution not only saves packaging space but also ensures that medicines remain in optimal condition throughout the entire shelf life, providing reliable protection for pharmaceutical packaging quality and stability.

In the field of pharmaceutical packaging, through ingenious design, the combination of PVC plastic blister packs and aluminum-plastic blister packs with WiseSheet polymer desiccant sheets not only shields medicines from external humidity and factors but also showcases the best display effects on shelves. This innovative desiccant solution provides robust support for ensuring the stability and effectiveness of medicines. Through continuous innovation and improvement, we can continuously enhance the quality of pharmaceutical packaging and offer higher levels of assurance for the storage, transportation, and use of medicines.