"Packaging is Part of the Test"

Application of Polymer Desiccant in Lateral Flow Immunoassay Test Packaging

Background

Scientific packaging plays a crucial role in addressing many challenges in diagnostic reagents. However, there are still some issues in current diagnostic reagent packaging that have not been optimally resolved. Moisture is a critical challenge in diagnostic reagent packaging. Temperature fluctuations during transportation can lead to the generation of moisture and condensation inside the packaging. The commonly used nitrocellulose membrane and conjugate pad materials in lateral flow immunoassay test strips are treated to be hydrophilic. Excessive moisture can cause a decline in reagent quality, affecting the accuracy of test results. Although measures such as humidity-controlling materials and the use of desiccant packets have been adopted to control moisture, there are still some problems in practical applications:

- The use of desiccant requires additional operational steps and time, affecting production efficiency.

- To avoid desiccant contacting the reagent, sufficient space inside the packaging needs to be ensured, increasing the amount of packaging material and the volume of air inside the package. As a result, the shelf life of most diagnostic reagents remains at only one year, and the impact of moisture on reagent quality and stability still exists.

- The size of packaging is influenced by the desiccant, occupying more transportation volume and weight, leading to increased transportation costs.

Therefore, the moisture-proof packaging solutions for diagnostic reagents can be further researched and innovated to find more effective moisture control methods, optimize the application of desiccants, and improve packaging design. The polymer desiccant was developed as an innovative solution to address the challenges faced in diagnostic reagent packaging. With the fundamental goals of automated production, extended shelf life, and convenient transportation, it provides diagnostic reagents with more suitable packaging solutions.

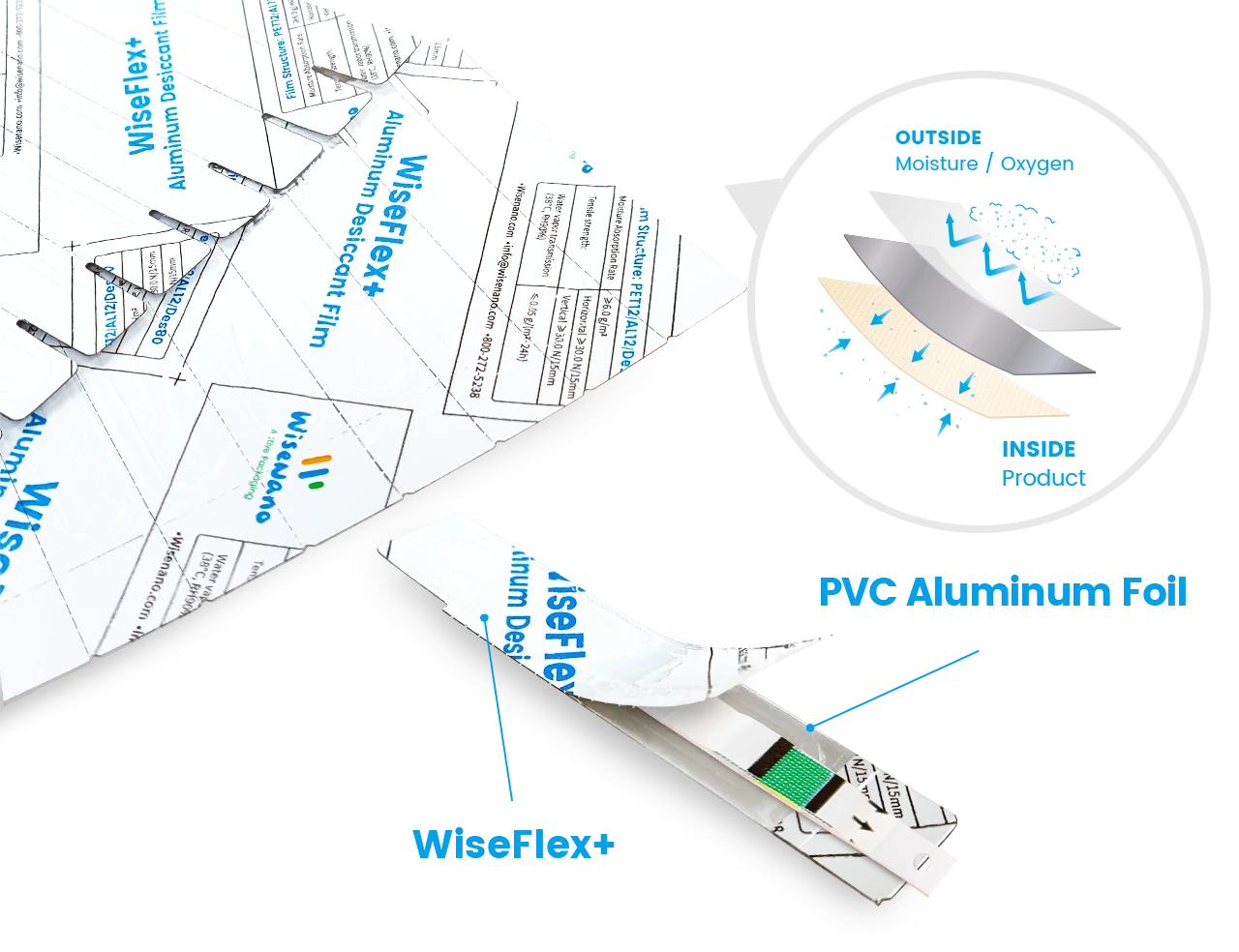

Solution 1

This unique packaging solution is designed specifically for lateral flow immunoassay test strips, utilizing a structure consisting of a rigid PVC aluminum foil baseplate with an easy-to-peel WiseFlex+ aluminum desiccant film cover. It offers several advantages: the aluminum desiccant film cover effectively isolates external air, absorbing internal moisture, thereby extending the shelf life of the reagents; the rigid PVC aluminum foil baseplate provides flat support for the packaging, preventing bending and curling; the body-fitted packaging design reduces the contact area between internal products and air, reducing the risk of moisture. Moreover, this design saves packaging materials and the additional steps of placing desiccant, allowing for mechanical automation during production. It also saves transportation volume, enhancing packaging’s cost-effectiveness. Notably, the WiseFlex+ aluminum desiccant film employs an easy-to-peel design for user convenience. Considering its outstanding features and wide application areas, this packaging solution brings innovative improvements to the storage, use, and transportation of diagnostic reagents.

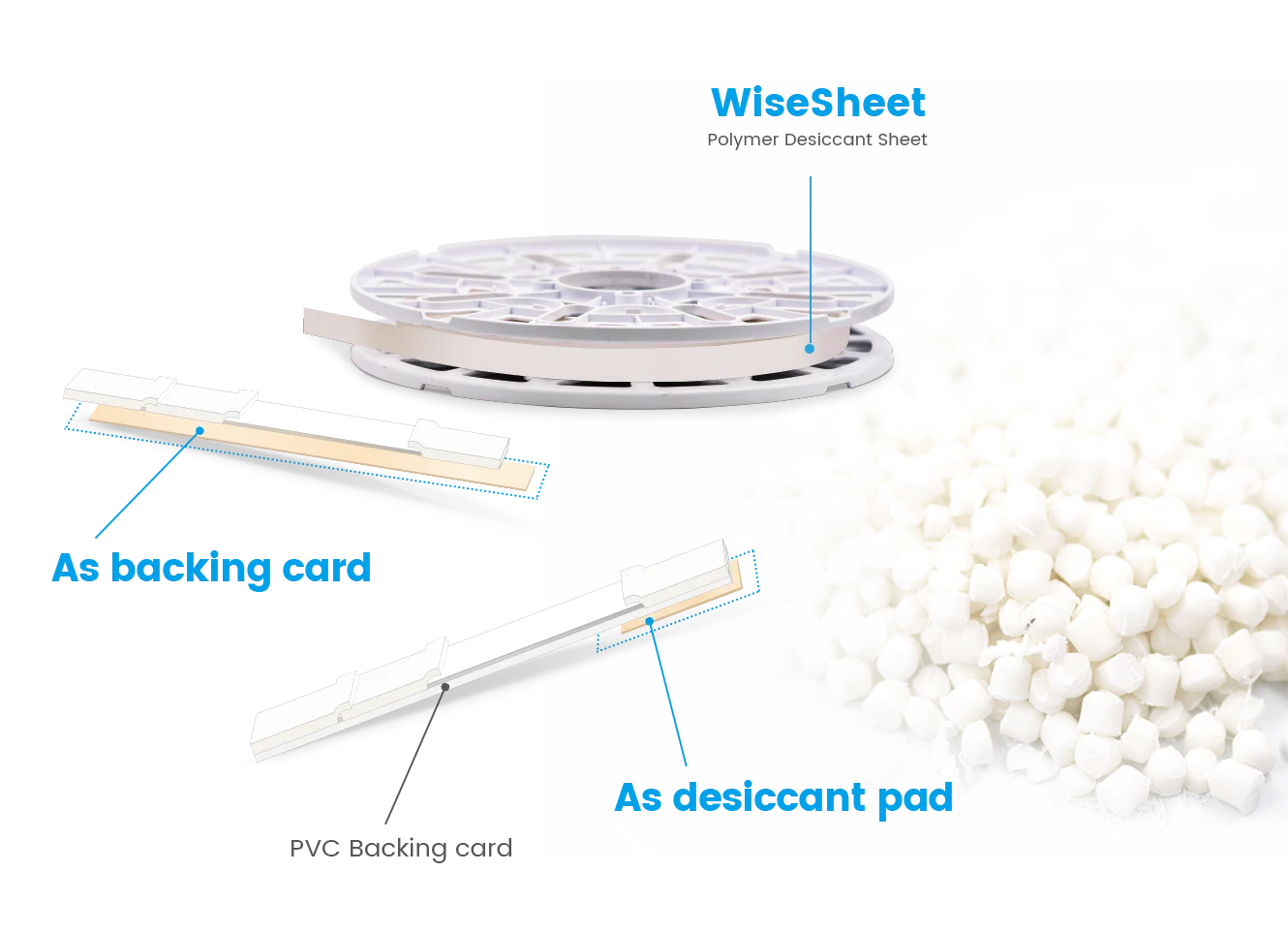

Solution 2

WiseSheet is a cuttable desiccant sheet that can be affixed under the backing card (underneath the absorbent pad side) or replace the common backing card, providing full support to the diagnostic reagents. The WiseSheet packaging solution features the following characteristics: as a part of the test strip, it reduces the prominence of the desiccant; the sheet is securely attached and not easily detached, avoiding friction with the test strip, ensuring safety during use; this design also saves packaging materials and transportation volume, eliminating the need for additional space for desiccant packaging; furthermore, the thickness of the sheet is adjustable, facilitating adjustments according to needs; using a carrier reel allows for machine automation, reducing the steps of placing desiccant and enhancing production efficiency while lowering labor costs. This solution is applicable to both test strips and test kit packaging and does not affect the original design of the test kit.

Solution 3

WiseSheet stickers as an intelligent packaging solution optimize the packaging efficiency of test kits. By adhering the stickers to the interior wall of ordinary aluminum foil pouch packaging, it boasts several unique features: firstly, it absorbs internal moisture, effectively extending the shelf life of the test kit; secondly, since it only requires materials of the test kit’s size, it saves packaging materials and maximizes space savings by reducing the air (oxygen and moisture) content inside the packaging; furthermore, the use of stickers avoids the risk of desiccant wear and tear on the pouch, ensuring the quality and integrity of the test kit; finally, adopting a carrier reel format allows for compatibility with sticker packaging machines, improving production efficiency. Considering these advantages and its extensive application areas, WiseSheet stickers exhibit excellent performance in test kit packaging, significantly improving performance and efficiency without substantially altering the original packaging and test kit design. It is a safe and innovative packaging solution.

ESG

In the past few decades, the field of diagnostic reagents has undergone rapid development. From the early use of complex laboratory techniques to the current portable test strips, the advancement of diagnostic reagents has brought about tremendous changes to the medical industry and gradually expanded its applications. Among them, lateral flow immunoassay test strips are an important form, enabling rapid diagnosis and monitoring by detecting specific biomarkers in urine, blood, or saliva. After experiencing the COVID-19 pandemic, the demand for rapid and accurate diagnostics has increased significantly, presenting the diagnostic reagents industry with greater challenges and opportunities.

- Material conservation, the application of polymer desiccants makes diagnostic reagent packaging more compact and efficient. By optimizing the design and use of desiccants, the internal air volume within the packaging is reduced, leading to decreased material consumption. This helps to reduce resource usage, minimize environmental impact, and mitigate waste generation, contributing to sustainable material management.

- Cost savings, the innovative solution of polymer desiccants can lower packaging production costs. Not only does it reduce the usage of packaging materials, but it also streamlines the production process, resulting in reduced labor and energy costs. This is crucial for enhancing the economic sustainability and long-term development of businesses.

- Labor efficiency, the automation of polymer desiccant application makes the process of desiccant placement more intelligent and efficient. With no need for additional manual steps, mechanized automation saves human resources. This enables companies to better allocate their workforce, enhance production efficiency, and create more valuable job opportunities for employees. Overall, the application of polymer desiccants in solving moisture issues not only improves packaging efficiency but also aligns with ESG principles by conserving materials, saving costs, and optimizing labor. It not only brings economic benefits to businesses but also contributes to environmental protection and social sustainable development. Moving forward, the continuous innovation and application of polymer desiccants will continue to play a positive role in the ESG domain.

Summary

Packaging plays a crucial role in the production of diagnostic reagents, providing not only product safety and protection but also adding product features and advantages to meet user needs. In addressing the challenges in diagnostic reagent packaging, we have introduced three innovative packaging solutions: WiseFlex+ aluminum desiccant foil packaging, WiseSheet stickers, and WiseSheet cut-to-fit. These three innovative packaging solutions effectively address the moisture challenge, successfully extending the shelf life, while achieving savings in packaging materials, increased production efficiency, and reduced transportation costs. Through these unique packaging designs, we have successfully optimized the packaging of diagnostic reagents, making them more efficient and reliable in logistics and transportation, thus bringing greater opportunities and challenges to the diagnostic reagents industry. As packaging is an essential aspect of diagnostic reagent production, becoming an integral part of diagnostic reagents, WiseNano will continue to innovate in the field of polymer desiccants, creating greater value and better experiences for diagnostic reagent manufacturers and customers.